Description

Safety Glasses for MLS® Laser

Description

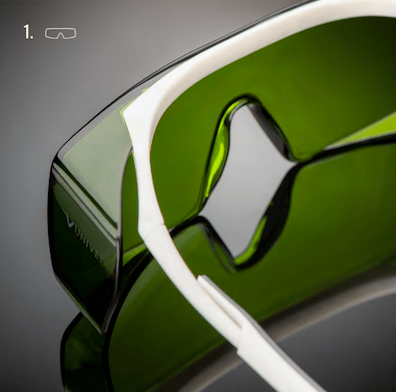

Our practitioner safety glasses have been designed to meet MLS laser specifications precisely. They not only protect from the exact wavelengths emitted by our lasers but also allow you to still see the base unit screen and laser diode guide-light. They are made to meet Australian safety standards of at least OD-5.

Glasses care

A colour film has been applied to the lenses, and they should be treated with the same care as prescription glasses to avoid damage to the film and ensure they are still providing protection. We understand you want to minimise the cost to your practice by ensuring its longevity, so we recommend the following practice for cleaning and maintenance.

- Use mild soapy water or a quality lens cleaner spray when cleaning your laser safety glasses

- Please thoroughly dry the glasses with a soft cloth (non-abrasive – e.g., microfibre) after cleaning them, and make sure you remove any cleaner residues.

Requirements

MLS® wavelengths consist of a pulsed wave at 905nm and a continuous wave at 808 nm.

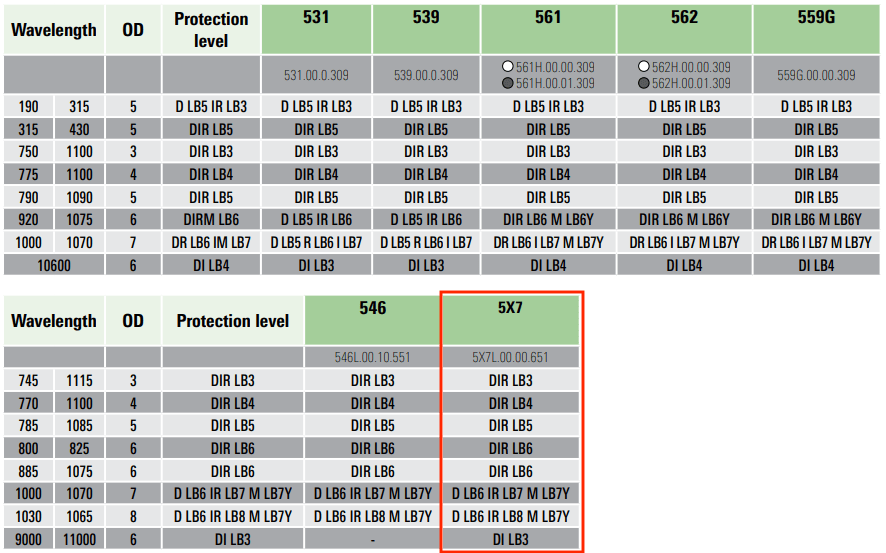

Protection recommended for Mphi by the manufacturer ASA, is:

- DI 808 – 905 LB5 (according to UNI EN 207:2010 standards)

- OD≥5 @ 808-905nm (according to ANSI Z136.7 standards)

The supplied glasses are rated at 885 – 1075 LB6 = OD6, higher than the requirement.

Glasses supplied

The glasses supplied are rated and labelled using the European LB scale according to EN 207.

This indicates that they absorb laser light of a specified wavelength and can also endure a direct hit from the laser without breaking or melting.

In this regard, the European standard is stricter than the Australian Standard, which only governs the required optical density.

For comparison, an LB 5 is equivalent to an OD 5, and it also indicates that the glasses can withstand a continuous wave laser for 10 seconds or 100 pulses from a pulsed laser.

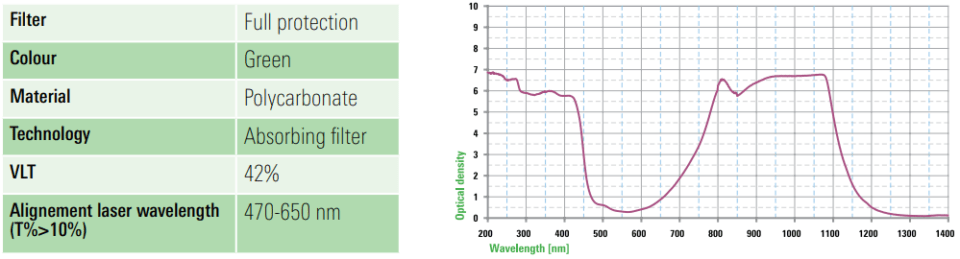

This graph shows the OD of the filter (UL-1005) used in the supplied glasses – the OD is over 6 for the required wavelengths:

In the table, the equivalence of the OD and LB for this lens filter is evident – the number in the OD column matches the number in the Protection level column.